Surelock

by Project Heaven

Specialist metal stitching repairs for classic, veteran and vintage cars

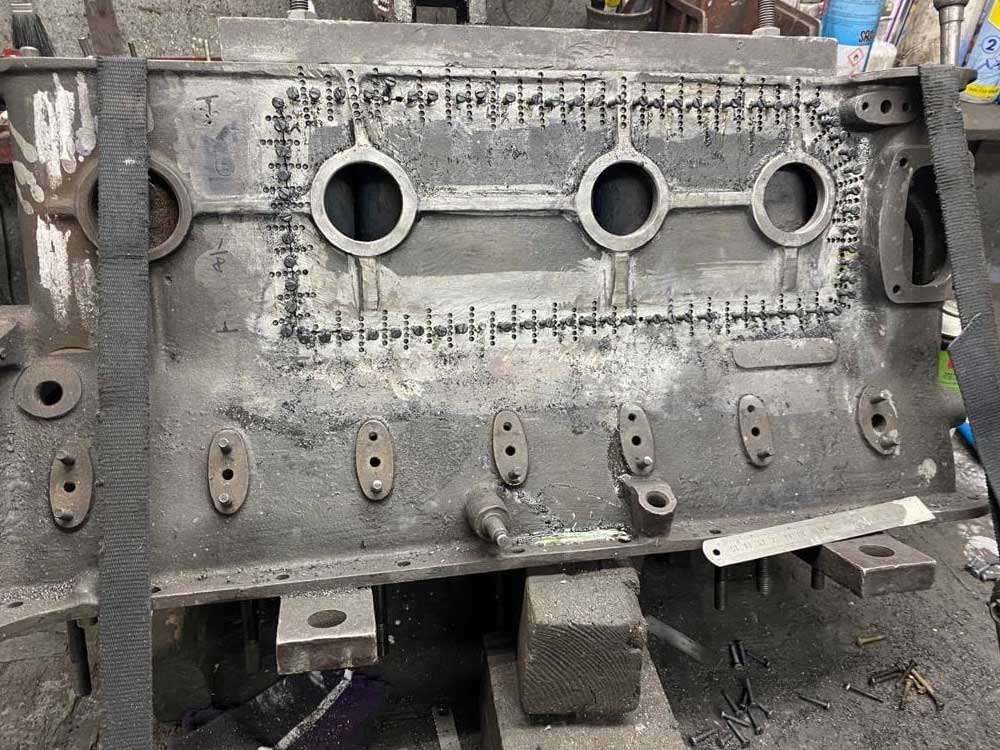

Surelock Casting Repairs specialise in the repair of cracks in veteran, vintage and classic road and racing car cast iron and aluminium cylinder heads, blocks, transmission casings and other components. The mechanical process of cold metal stitching enables our engineers to repair engine components in situ if required, reducing the need to strip down a running engine, and saving our customers both time and money. Our service reduces the scrapping of rare and valuable castings and expensive components.

We have the technical expertise and tools required to repair a wide range of metal castings without the use of welding. This is one of the most important of the many advantages of cold metal stitching: no heat is applied and thus the possibility of heat distortion is entirely avoided. If you think you may benefit from our services, please call, or email us with photographs and a description of the damage. We will endeavour to respond promptly.

Why Surelock?

We specialise in the repair of cracks in cast iron and aluminium cylinder heads, blocks, transmission casings and other components. Our process and service include:

Complete avoidance of heat distortion & cracking as this is a cold repair process

No local changes to the metallurgy & tensile strength of the castings

Specifically designed for old car castings in the optimal sizes needed

Our locks are made from a steel alloy which is unique to us and is as strong as and more ductile than any other on the market

Relative thermal expansion coefficient as the parent material, ensuring they do not become loose during heat cycles

Surelock has had no known failures in 60 years

We pressure test every repair and can offer ceramic impregnation for extra protection

All of our repairs come with a 6 month warranty

Why Cold Casting Repairs?

The chemical composition of metals has changed and evolved considerably since the early days of the automobile in the late 19th century. Therefore, modern welding repair techniques including laser welding for cracks or crevices in older cast iron and aluminium, are often unsuccessful. Inconsistencies & inclusions in the metal are quite common, especially in earlier vehicles, often making successful welding completely impossible.

The heat applied during the welding process can sometimes cause further damage. The tensile strength of the metal at the repair site is altered during the welding process, leading to potential post-repair cracking. To prevent this, the method of cold cast repairs has been developed, perfected, and successfully used for many years. If a block has already been welded, the Surelock System of Cold Casting Repairs could still be used to save the block. If the block can be repaired, we will remove and replace the weld with a stitched repair. We finish the job by ceramically impregnating the block.

We also have very extensive in-house welding skills and facilities and can advise in those cases where welding might be more appropriate, for example where material needs to be added and distortion can be mitigated.

Our History

Surelock Casting Repairs was founded almost 60 years ago, in 1966, by Bev Hood. With his fellow engineering colleagues, he further developed the cold metal stitching process designed for heavy engineering repairs initially patented in the late 1930s by Metalock.

Bev was an expert toolmaker and machinist, with a comprehensive understanding of metals. This knowledge, combined with his skill set enabled him to perfect this new form of casting repair for smaller castings.

His son, Nick Hood, took over the family business, running it successfully for 35 years. Nick, who remains a consultant for Surelock, has now passed on his expert knowledge to Peter Bulbick of Project Heaven.

Peter is an expert in the Surelock System of Cold Casting Repairs and is focused on continuing the high-level work and customer service that Surelock is known for.

Get in Touch

If you think you may benefit from our services, please call, complete the contact form on this page, or email us with photographs and a description of the damage. We will endeavour to respond promptly.

+44 (0)1572 722051